These 3 Common Pitfalls Make it Virtually Impossible For Building Owners to Prevent Metal Roof Leaks

With one simple upgrade, building owners and managers can reap the benefits of a dry building for decades! No Replacement Necessary!

How The Process Works

Eliminate Rust

Rust removing solvent is added in the preparation stage to remove any loose rust to the existing roof surface.

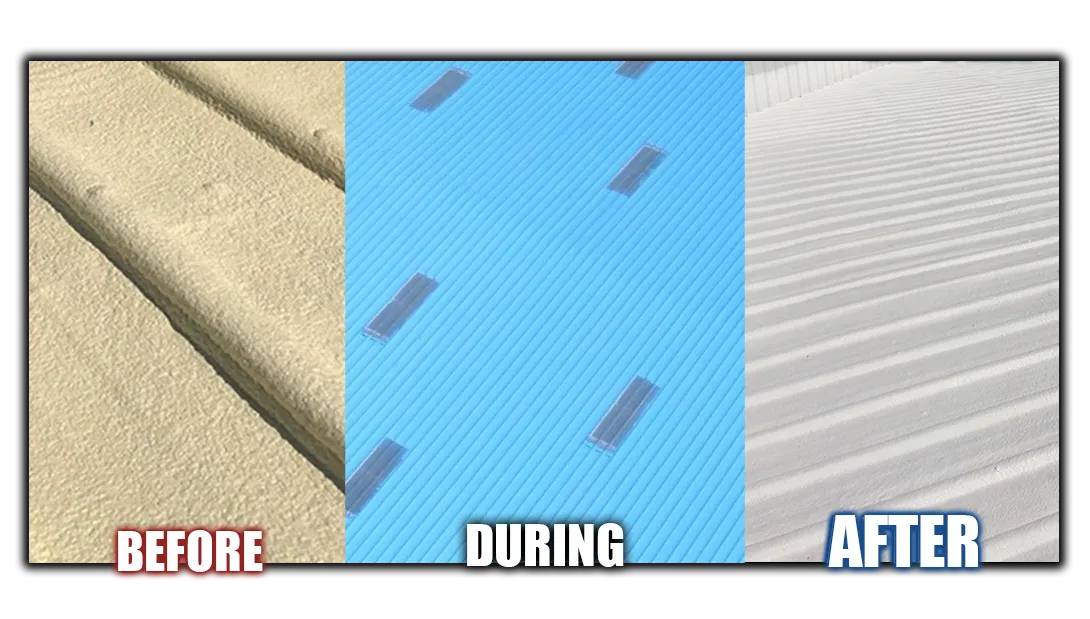

Eliminate Seam Exposure

Fabric or fiber embedded coating is applied to all of the seams increasing the durability of the roof and eliminating leak entry points at the seam.

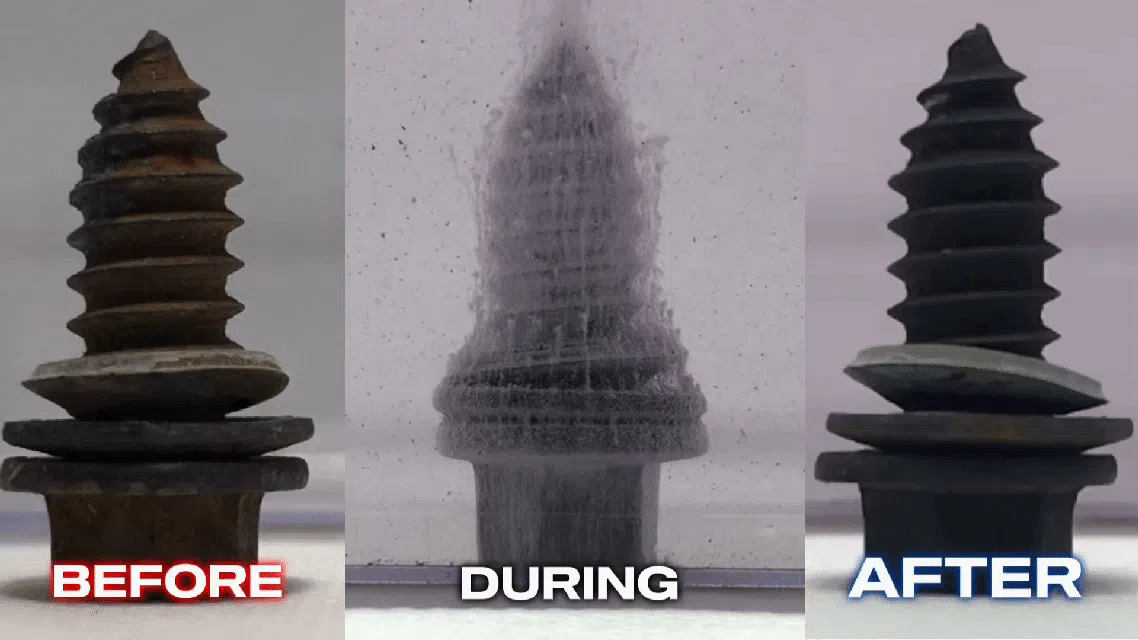

Eliminate Fastener Exposure

Fasteners are secured and sealed to prevent backing out of screws and eliminating the leak entry points.

Upgrade: Insulated Roof System

High grade foam is applied over the entire roof surface, giving you year round energy savings from the increase insulation value.

A System Just For You

No matter the roof type, Ember Coatings will provide you with the most efficient solution to meet your budget.

Ribbed Panel Systems

Standing Seam Systems

Insulated Foam Systems

Benefits Include:

100% Tax Deductible

According to tax code section 179 a a commercial roof restoration systems classifies as a repair and can be completely written off

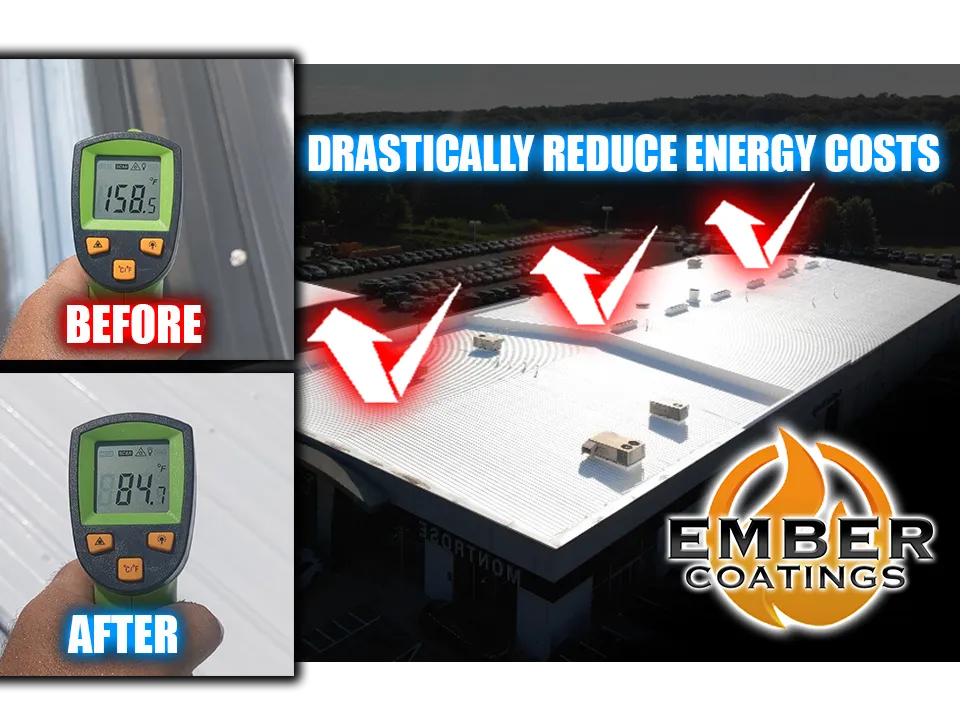

Massive Energy Savings

The high reflectivity of the coating dramatically reduces the surface temperatures of the roof. Building owners can sometimes see energy bills decrease up to 40%.

Environmentally Friendly

No disposal means no landfill waste cluttering up the local landfills. Also, the reduced surface temperatures will cause less load stress to your units and consume less electricity from the grid.

Zero Downtime

These systems are applied directly over the existing roof surface without any disruption to inside operations. Allowing you to run your company without any downtime.

Maximize Cost Effectiveness

Restoration systems take a fraction of the time compared to a replacement and can be done with less manpower resulting in lower labor costs.

Maximum Leak Protection

With manufacturer warranties of up to 20 years building owners can enjoy the benefits of a dry building for a very long time.

Some of Our Projects:

How to Get a Return

on Your Investment

The reduced surface temperatures from the high reflectivity coating dramatically reduces the energy consumption inside the building resulting in lower energy bills.

Premium Products Used

Take this 30 Second survey below to check if you qualify.

Your information is 100% secured & protected.

@ 2024 Your Company Name - All Rights Reserved